DZQ-1650 Multi-blade Hydraulic Stone Cutting Machine【Stone Machine,Stone Cutter,Stone Cutting Machine,Block Cutter】

The DZQ-1650 Hydraulic stone cutting machine is a multi-blade block saw for sawing kinds of stone blocks into slabs of varying thickness with up to 22 pc of diamond saw blades at the mostly..

The structure of such machine featured of simple and functional,is made up of a sturdy welded stabilized cast iron & steel to ensure maximum stability and utmost precision during sawing.

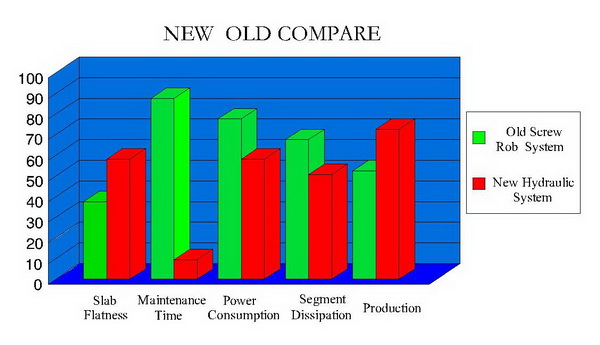

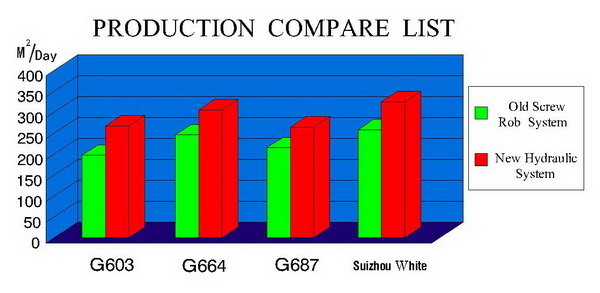

The up/down system is setup of Four hydraulic pressurize column,to ensure maximum protection against rust.Patented Lubrication System can vastly reduce maintenance frequency and maintenance costs which means a perfectly block cutter compared with traditional same kind of machine.

1: Up/Down sliding ways are made up of chrome-plated round steel to minimze cutting clearance and trembling,and to endure the using life of machine.

2:Patented locking Device is used to reduce the spacing of parts of machine from friction,this will maximum increase the cutting precision.(Alternative)

3. Up/Down Column movements are lubricated by grease (Butter) which only need to be added up to only once every three months. It will significantly reduce maintenance frequency.

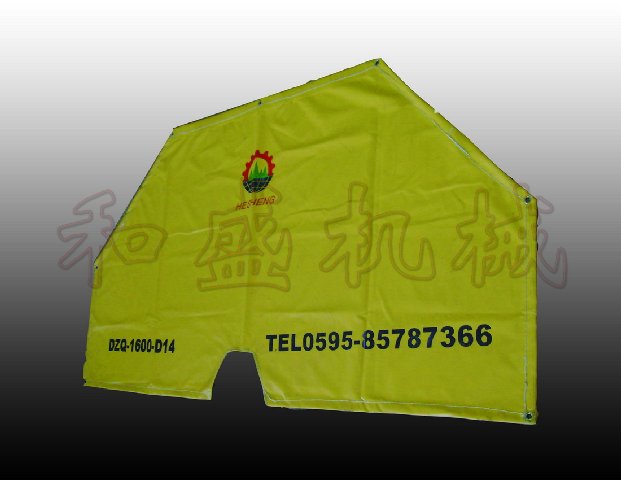

4. A new composite materials called "nano-nylon" cloth which with the characteristics of waterproof, dustproof, anti-rally of anti-wear , was used; and the use of detachable zipper will enable a easy replacement of it .

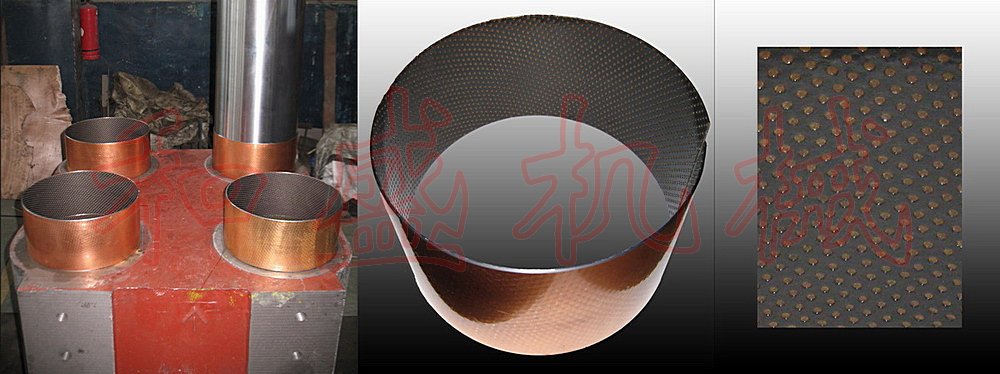

5. A guiding polymer materials (Teflon, Brand Dupont) was used on the contact surface between up/down column and seat . Such guiding material is rolling into a circular storage pits, in less oil or oil under the conditions of space off to work with a low coefficient of friction, wear resistance and long service life, etc..

6. Up/Down oil cylinder using the combined oil seal , imported from German , imported German, composited with a flexible seal ring, two retaining rings and two block-oriented ring which is a five-pieces set of piston seals and with much several times of service life compared with other common sealing.

7. ALL hydraulic & Electric Components used are the optimized quality from domestic and abroad.

8.Processing precision of machine parts and components are ensured,due to the adoption of CNC drilling machine.

9.Use CNC boring lathe to process the hole of sliding way column and headstock,to ensure the concentric and stability.

10.Sliding ways of up/down system are quantity proceed by completely new grinding machine,for the purse of high precision and quality.

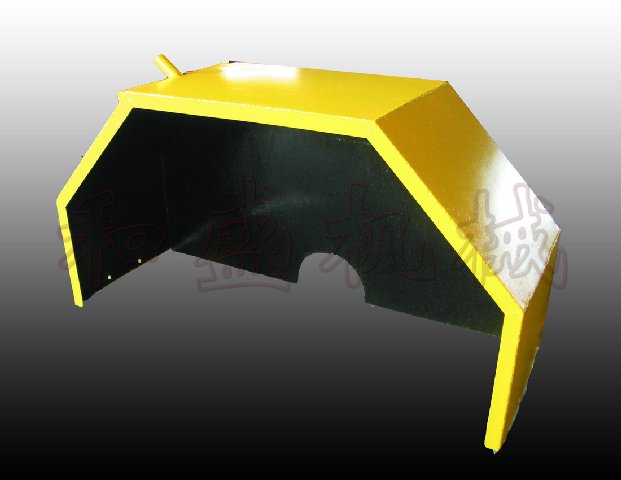

1:Blade Cover is made by Nyion Paulin,which is convenience for replacing blades.

2:Blade Cover is made up of 3mm steel-plate,painted with asphaltum for anti-rust.

3:All hydraulic & Electric Components used are the optimized quality from domestic and abroad.

4:Worktable is reinforced by Standard Two-Double channel Steel。